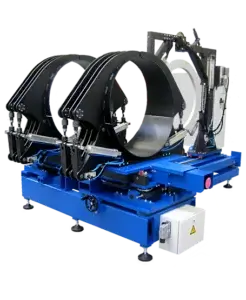

The RBSM 900 pipe bend welding machine is a specialized welding system for the production of pipe bends from PE pipes in the district heating and heating sector.

This machine is designed for casing pipes with a diameter of 900 mm and offers the following main features:

Vertical alignment for pipe bend production

Servomotorized angle adjustment from 0° to 22.5° per side, infinitely variable

Automated welding process with electronic control

Pneumatic clamping system for secure pipe fixing

Split heating elements with non-stick coating

Pneumatic opening of the heating elements

Electrically operated linear rail system for precise heating element movement

Option for split planer for surface treatment

Reducer inserts available for smaller pipe diameters

Extendable to pipe diameters up to 1200 mm