More Information on the Production of Welding Wire for Plastic Welding:

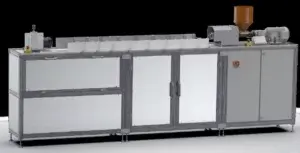

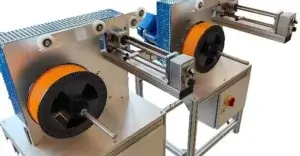

A wire extruder is a specialized machine used in plastic processing for the production of welding wire. Particularly in the production of plastic welding wire with diameters of 3, 4, or 5 mm, the wire extruder plays a central role.

The process is based on the extrusion method, where thermoplastic materials are melted in a heated extruder and then pushed through a precisely constructed nozzle to produce a wire with consistent shape and exact diameter.

Functionality and Technology

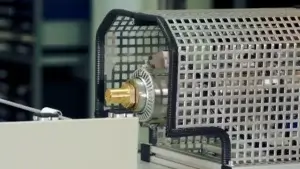

Inside the wire extruder, the raw material, usually in the form of granules or powder, is first preheated and homogenized through mechanical shearing. Using a rotating screw drive, the material is further heated, liquefied, and transported to the extrusion area. Here, the specially manufactured die is used to shape the welding wire to the desired size.

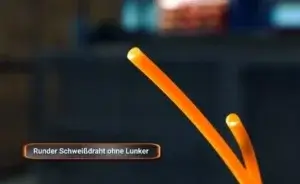

The resulting consistency in shape and diameter is crucial for subsequent applications in plastic welding technology.

Process Parameters and Quality Assurance

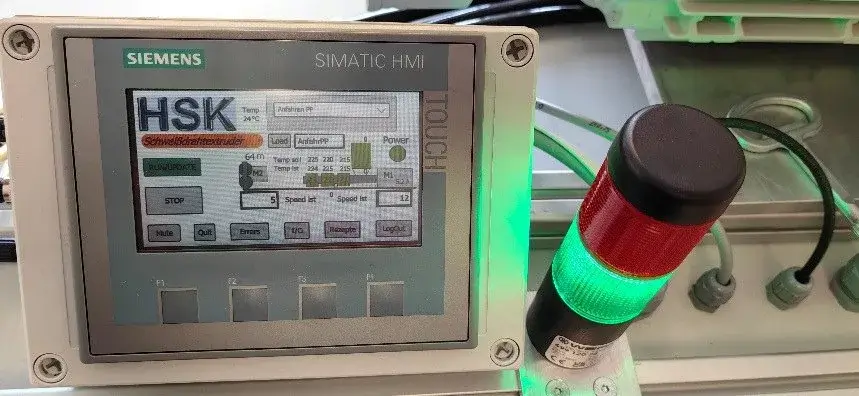

A crucial aspect of wire extrusion is the precise control of temperature, pressure, and feed rate. These parameters must be optimally coordinated to ensure uniform material distribution and consistent wire quality. Modern wire extruders feature advanced control systems that allow continuous monitoring and adjustment of process conditions.

This reduces waste and ensures high product quality, which is particularly important for welding wire used in critical joining processes.

Areas of Application and Advantages

Plastic welding wire, manufactured with wire extruders, finds application in numerous industrial sectors, such as vehicle construction, the packaging industry, or the construction industry.

The precise manufacturing and the ability to produce various diameters such as 3, 4, or 5 mm allow for flexible integration into different welding processes.

The advantages include:

- High Precision: Consistent wire dimensions ensure stable weld seams.

- Efficiency: High throughput is achieved through continuous production and automated control systems.

- Material Diversity: Various thermoplastic materials can be processed, enabling diverse applications.

- Energy Efficiency: Optimized process parameters minimize energy consumption and reduce production costs.

Outlook and Conclusion

Overall, the wire extruder represents an essential technology in the production of plastic welding wire at the customer’s site, impressing with both its flexibility and high production quality.

The ability to precisely realize specific wire diameters makes it a valuable tool in modern industrial manufacturing processes.