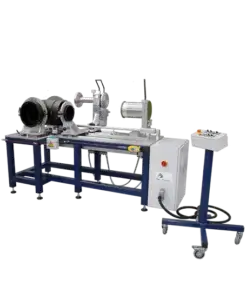

Pipe welding machines are characterized by their stable and reliable design.

A torsion-resistant base frame

Precise linear guides

High accuracy and resilience

Computer-controlled systems

Hydraulic mode of operation

Digital displays and control systems

These machines are versatile and suitable for tasks such as welding PE, PP, PVDF and other thermoplastic materials

They offer programmable welding parameters and precise temperature control for the required melting temperature

To improve efficiency and quality, the following features can be integrated, such as

PTFE-coated heating element

Electric planer

Automatic creation of welding records for documentation and inspection

Special clamping tools for T, Y and X weld seams

Option to produce weld seams at various angles (45°, 60° and 90°)

Modern pipe welding machines are characterized by good weld seam formation and enable precise, efficient and versatile processing of plastic pipes in various industrial applications.