Nowadays, most water, wastewater and rainwater transport systems are made of plastic pipes with diameters of up to 4.5 meters.

Processing these large pipes requires exceptional precision and strict adherence to safety regulations.

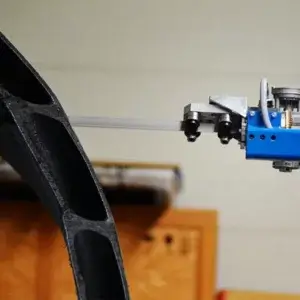

Our large pipe saws are specially designed to meet the requirements of modern production processes.

Almost the entire cutting cycle is computer-controlled, so that the employees only have to monitor the machine.

All advantages at a glance

- Innovative design:

Movable saw arm and open working area. - Automated cutting:

Segment cuts without moving the pipe. - Ergonomic work platform:

Low position facilitates loading and unloading. - Simple saw blade change:

No elevator or ladder required. - Precise cutting adjustment:

Cutting position can be adjusted without pipe movement. - Versatile cutting:

Precise cuts at different angles.

New standard for large-diameter plastic pipes

Compared to traditional solutions, our sawing system enables time savings of up to 50-60% when cutting large-diameter plastic pipes.

The precise processing ensures smooth cut surfaces that require no reworking and guarantee a perfect fit of the individual parts.

Thanks to the flexibility in the choice of saw bands, various materials with wall thicknesses from a few millimeters to over 140 mm can be processed efficiently.

Security features

All large pipe saws are equipped with effective safety devices as standard, including:

- Emergency switch

- Overload protection modules for drives and electronic components

- Electronic brake on the cutting belt

- Laser projection of the cutting line

- Ease of use

Each saw is controlled via a large touchscreen control panel.

The operator can set the cutting parameters step by step by selecting the corresponding symbols.

Saw blade change

Simple, safe and fast

Our system sets new standards for saw blade changes in terms of safety and efficiency.

Normally, replacing the saw bands in large saws is time-consuming and complicated, often requiring ladders and special tools.

With our saws, the arm can simply be lowered without the need for external cranes or lifting devices.

Efficient and precise cuts

With the large pipe sawing system for plastic pipes, all necessary cuts can be made cost-effectively.

A wide range of contour cuts are possible without having to move or turn the pipe.

This ensures unprecedented accuracy and quality as well as considerable time savings.

Standard cuts that are included with every large pipe saw for plastic pipes

- Infinitely adjustable angle cut in the range from 45° to 135

- V-cut on the main pipe to create T-pieces

- V-cut on the outlet pipe to create T-pieces

- 90° straight cut for cutting pipes to length or for pipe end machining

- 67.5°/22.5° cut on the outlet pipe for creating Y-pieces

- 90° cross-section

Other optional additional cutting options

- Creation of flexible Y-pieces with variable angle in main and outlet pipe

- Radius cuts on the outlet pipe

- Programmable cutting sequences that can be saved as so-called recipes

- Customizable cutting sequences for every application

Scope of delivery

- 1x “GR-BSM” basic machine

- 1x control panel

- 1x operating instructions

- Additional options and accessories selected