Pipe welding machines for plastics are therefore specialized machine tools that are used for welding plastic pipes in various applications.

These machines enable safe, efficient and precise joining of plastic pipes, which is crucial in many industries, such as the chemical industry, water supply and wastewater disposal.

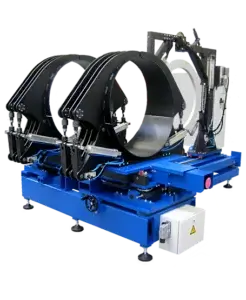

We supply butt welding machines for pipes:

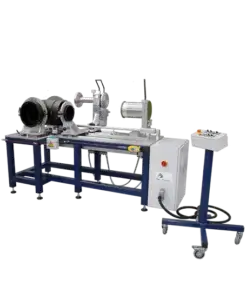

Trench welding machines

We also supply trench welding machines for welding pipes and fittings made of PE-HD, PP and PVDF and workshop welding machines for the production of pipe fittings up to AØ 1600 mm on request.

Pressure pipes for liquids and gases or thin-walled PE casing pipes, such as those used for district heating pipes, can be welded.

The machines are built according to international norms and standards and enable smooth production.

Depending on the pipe size, manual, semi-automatic and fully automatic CNC machines are available. With PLC control, a computer takes over all settings and work processes after entering or calling up the necessary parameters in order to achieve optimum and reproducible results in accordance with DVS guidelines.

At the end of the welding process, the results are saved and printed out.

Trench welding machines can be used to weld pipe to pipe or pipe to fitting, while the workshop machines can also be used to produce segmented bends, branches, junctions and crossings. The machines can be flexibly equipped with additional fixings and brackets, which can also be purchased at a later date.

Large trenching and workshop machines can optionally be equipped with an electric crane for lifting the pipe cutter and welding level in and out.

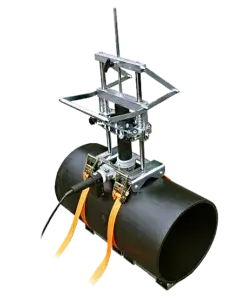

We have our own machines in our range for the production and repair of pipelines in hard-to-reach, confined or vertical areas.

General information on types of pipe welding machines:

- Electrofusion welding machines:

These machines use a heating coil to heat the ends of plastic pipes. After heating, the pipe ends are joined together and the molten material forms a solid weld seam when it cools down again. - Butt welding machines:

These machines bring the plastic pipes to be welded into direct contact and heat the pipe ends. The hot pipe ends are then joined together, creating a homogeneous weld seam. - Extrusion welding machines:

Here, a molten plastic layer is extruded between the pipe ends to be welded. After extrusion, the pipe ends are joined together and the molten material forms the weld seam.

Merkmale:

- Temperature control:

The machines have precise temperature controls to ensure that the plastic pipes are heated to the required melting temperature. - Pressure control:

Some machines offer the option of controlling the welding pressure to ensure uniform fusion of the pipe ends. - Automation functions:

More modern pipe welding machines for plastics can be equipped with automated controls that can monitor and control the entire welding process. - Adaptation to pipe diameters:

The machines should be able to adapt to different pipe diameters to ensure flexibility in production. - Robust construction:

Due to the often demanding environments in plastics processing, these machines are robustly built to withstand industrial requirements.

Anwendungen:

- Water supply and wastewater disposal:

Connection of plastic pipes for drinking water supply and wastewater disposal. - Chemical industry:

Used in chemical processing to connect pipes for the transportation of chemicals. - Agriculture:

Used for connecting plastic pipes in agricultural irrigation systems. - Construction industry:

Connection of plastic pipes for construction projects, e.g. in building drainage. - Industrial applications:

Joining of plastic pipes for various industrial applications, depending on the requirements of the specific industry.

Plastic pipe welding machines play an important role in the production of reliable and safe plastic pipelines used in a wide range of applications.