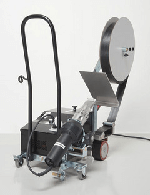

Advantages of Tarp Welding with an AKU Hot Air Welding Machine

The use of an AKU hot air welding machine offers numerous advantages in the processing and repair of tarps.

Through precise temperature and speed settings, a uniform, durable, and waterproof weld seam is produced, guaranteeing high durability.

Thanks to the automated guidance, the welding machine works particularly quickly and efficiently, saving work time and ensuring consistent welding quality.

This makes it ideal for industrial use in the production and repair of truck tarps, advertising banners, tents, and other PVC or PE materials.

Moreover, the use of a hot air welding machine reduces material and labor costs, as no additional adhesives or sewing work is required.

The long-lasting welded joints provide an environmentally friendly and sustainable solution by extending the lifespan of the tarps.

Tarp Welding with an AKU Hot Air Welding Machine – Background and Benefits

Welding of tarps is a proven method for permanently and securely joining materials such as PVC, PE, or other thermoplastic fabrics. AKU hot air welding machines enable precise, efficient, and high-quality processing of these materials.

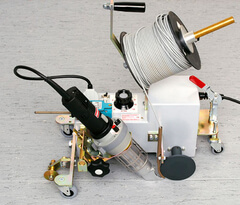

Background: How Does Hot Air Welding Work?

In hot air welding, the surface of the tarps is melted by a targeted hot air stream. The heated material edges are then joined under pressure, creating a seamless, durable, and waterproof weld seam.

The temperature, speed, and contact pressure can be precisely controlled, guaranteeing consistently high-quality results.

Advantages of Tarp Welding with an AKU Hot Air Welding Machine

Strong and Long-lasting Connections

- The welding creates a homogeneous material bond that withstands high loads and does not lose strength over time, unlike adhesive bonds, for example.

Waterproof and Weather-resistant Seams

- The welded seams are absolutely tight, which is crucial especially for truck tarps, tents, and advertising banners.

Efficiency and Time Savings

- Due to the automatic guidance of the welding device, processing is fast and precise, allowing large areas to be welded without much effort.

Cost Savings

- Unlike adhesive or sewing techniques, there are no additional material costs for adhesives or sewing thread. Additionally, long-lasting repairs postpone the need for new tarp purchases.

Environmental Friendliness

- The longer durability of welded tarps reduces waste and conserves resources, providing a sustainable alternative to replacing damaged tarps.

Easy Handling

- AKU hot air welding machines are user-friendly and allow for intuitive operation, enabling even less experienced users to achieve professional results.

Conclusion

With an AKU hot air welding machine, tarps can be welded efficiently, economically, and in an environmentally friendly manner.

Thanks to the strong, weather-resistant, and long-lasting welded seams, they are the ideal solution for professional use in the manufacturing and repair of truck tarps, advertising banners, tents, and other plastic fabrics.