- Semi-finished products

- Sheets

- Solid rods

- Solid rods PVC overview

- Solid rods PE

- Solid rods PP

- Solid rods PET

- Solid rods PBT

- Solid rods ABS

- Solid rods PMMA

- Solid rods PC

- Solid rods PA overview

- Solid rods POM

- Solid rods PSU

- Solid rods PPSU

- Solid rods PEI

- Solid rods PEEK

- Solid rods PVDF

- Solid rods ECTFE

- Solid rods PCTFE

- Solid rods FEP

- Solid rods PFA

- Solid rods ETFE

- Solid Rods PTFE

- Hollow rods

- 4-edge, flat, 6-edge bars

- Transparent tubes

- Standard profiles

- Foils

- Molded tubes

- Welding consumables

- Sustainable plastics

- Delivery Overview Semi-Finished Products

- Finished parts

- Ventilation mouldings

- Elbows and Sockets

- Tees

- Flanges

- Control Dampers, Control Shut-Off Dampers

- Throttle and Shut-Off Valves

- Throttle Valve with Handle, Socket on both Sides

- Butterfly Valve with Handle, Double-Flanged

- Throttle Valve Socket and Knob

- Butterfly Valve, Flange, and Rotary Knob

- Butterfly Valve Flange and Stepless Rotary Knob

- Throttle Valve Socket and Knob, Stepless

- Butterfly Valve, Hand Lever, Flange, 15° Detent

- Butterfly Valve Rotary Knob Socket 15° Grid

- Butterfly Valve Rotary Knob Flange 15° Grid

- Damper valve, continuously adjustable rotary knob, socket, 15° detent

- Butterfly valve, stepless rotary knob, flange, 15° detent

- Pipe Silencer with Socket or Flange

- Pipe Silencer with Flange, Baffle Length 500 Mm

- Pipe Silencer with Flange, Baffle Length 750 Mm

- Duct Silencer with Flange, Baffle Length 1000 Mm

- Pipe Silencer with Flange, Baffle Length 1250 Mm

- Pipe Silencer with Flange, Baffle Length 1500 Mm

- Pipe Silencer with Flange, Baffle Length 1750 Mm

- Pipe Silencer with Flange, Baffle Length 2000 Mm

- Pipe Silencer with Sleeve, Baffle Length 500 Mm

- Pipe Silencer with Socket, Baffle Length 750 Mm

- Pipe Silencer with Sleeve, Baffle Length 1000 Mm

- Pipe Silencer with Socket, Baffle Length 1250 Mm

- Duct Silencer with Socket, Baffle Length 1500 Mm

- Pipe Silencer with Sleeve, Baffle Length 1750 Mm

- Pipe Silencer with Socket, Baffle Length 2000 Mm

- Rain Hoods

- Ventilation Pipes

- Tee Plastic breech

- Saddle Branch

- Deflector Hood

- Roof Attachment 0° – 45°

- Slotted Gate Valve

- Backflow Caps

- Louvered Damper Flap

- Wall Penetration

- Bird Protection Grid, Chamfered at 30°

- End Cap with Socket

- Inspection Port

- Duct Stiffener

- PVC Spiral Hose

- Supply and Exhaust Air Grilles

- Machines & devices

- Hot air/warm gas welding devices

- Hot Air S

- MINI-Electronic and MINI-Electronic-SC

- Grand – S – Electronic

- Quick-S Elektronic

- Quick-L-switchable

- Hot Air Quick-L-electronic Forsthoff

- Quick-L-Electronic Potentiometer

- Oval-Q

- Oval-H

- Robust-L

- Hot Gas Welding User Sets

- APX100

- APX300

- Welding gun 200

- Welding gun 500 digital

- Hot Gas Welding Gun HSK700 – Penweld 505-A

- Hot air welding machines

- Welding nozzles

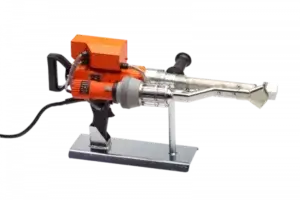

- Welding extruder

- Welding extruder HSK10 DE digital

- Welding extruder HSK10.2 DE digital compact

- Welding extruder HSK18 E

- HSK18 RSX welding extruder

- Welding extruder HSK22 RSX DATA

- HSK26 GSX welding extruder

- Welding extruder HSK28 RSX DATA

- Welding extruder HSK40 E

- HSK40 RSX welding extruder

- Welding extruder HSK60 DE

- Welding extruder HSK60 DE Granules

- Welding extruder HSK60.1 DE Granules

- Welding extruder heat protection

- Welding extruder transport case

- Welding wire extruder line

- Air compressor

- Air heater

- Welding mirror

- Socket welders

- Panel benders overview

- Panel bending machines

- Butt welding machines overview

- Plate welding machines

- Pipe welding machines

- Pipe band saw overview

- Orbital saw

- Auxiliary equipment

- Testing technology

- Hot air/warm gas welding devices

- Resources