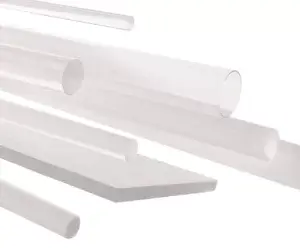

PC (polycarbonate) sheets:

Transparent, impact-resistant and versatile

PC (polycarbonate) sheets are high-quality plastic products that are characterized by their transparency, impact resistance and versatility.

Features and applications of PC boards:

Properties:

- Transparency:

PC sheets offer excellent optical clarity, comparable to glass, making them ideal for applications with visibility requirements.

- Impact resistance:

Polycarbonate is extremely impact-resistant and virtually unbreakable, which makes it suitable for applications with an increased risk of impact.

- Lightweight:

Despite their robustness, PC panels are lightweight, which facilitates handling and installation.

- Weather resistance:

They are resistant to UV rays and the effects of the weather, which means that their optical properties can be maintained over a long period of time.

remain intact. - Flame-retardant: Polycarbonate is generally flame-retardant and contributes to safety.

Applications:

- construction industry:

PC sheets are used in the construction industry for transparent roofing, skylights and façade cladding.

- Greenhouses:

Due to their light transmission, they are used in greenhouses for optimum lighting conditions.

- Advertising technology:

PC sheets are used for the production of lightweight advertising signs, displays and illuminated billboards.

- Security applications:

Polycarbonate is used for bulletproof glass, security windows and surveillance systems.

- electronics industry:

Used for transparent housings, covers and displays in the electronics industry.

PC sheets offer an excellent combination of transparency, impact resistance and versatility.

They are widely used in various industries where clear, robust and lightweight materials are required.