- About us

- Semi-finished products

- Sheets

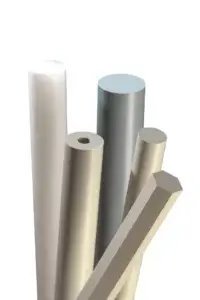

- Solid rods

- Solid rods PVC overview

- Solid rods PE

- Solid rods PP

- Solid rods PET

- Solid rods PBT

- Solid rods ABS

- Solid rods PMMA

- Solid rods PC

- Solid rods PA overview

- Solid rods POM

- Solid rods PSU

- Solid rods PPSU

- Solid rods PEI

- Solid rods PEEK

- Solid rods PVDF

- Solid rods ECTFE

- Solid rods PCTFE

- Solid rods FEP

- Solid rods PFA

- Solid rods ETFE

- Solid Rods PTFE

- Hollow rods

- 4-edge, flat, 6-edge bars

- Transparent tubes

- Standard profiles

- Foils

- Molded tubes

- Welding consumables

- Sustainable plastics

- Delivery Overview Semi-Finished Products

- Finished parts

- Ventilation mouldings

- Machines & devices

- Hot air/warm gas welding devices

- Hot air welding machines

- Welding nozzles

- Welding extruder

- Welding extruder HSK10 DE digital

- Welding extruder HSK10.2 DE digital compact

- Welding extruder HSK18 E

- HSK18 RSX welding extruder

- Welding extruder HSK22 RSX DATA

- HSK26 GSX welding extruder

- Welding extruder HSK28 RSX DATA

- Welding extruder HSK40 E

- HSK40 RSX welding extruder

- Welding extruder HSK60 DE

- Welding extruder HSK60 DE Granules

- Welding extruder HSK60.1 DE Granules

- Welding extruder heat protection

- Welding extruder transport case

- Welding wire extruder line

- Air compressor

- Air heater

- Welding mirror

- Socket welders

- Panel benders overview

- Panel bending machines

- Butt welding machines overview

- Plate welding machines

- Pipe welding machines

- Pipe band saw overview

- Orbital saw

- Auxiliary equipment

- Testing technology

- Resources